TANGO, Oyster 56 Sailing Yacht Flood Refit

April 6th, 2023

TANGO on route to Berthon Shipyard

TANGO was shipped from the British Virgin Islands for a refit in Lymington during the summer months after a partial flooding. Originally purchased from Berthon UK, via Berthon USA approximately six years prior to the unfortunate event; her American owner had fond memories of touring the offices and boatyard sheds at Berthon that employs over 150 sales, administration, project management, and skilled staff. Not being able to find a boatyard in the states close to a shipping port with the in-house facilities and skillset for such a complex refit, it was decided that TANGO would piggyback across the Atlantic to Southampton, where she was offloaded and towed a few miles to the centuries-old Shipyard in Lymington. Being built locally and fitted with a 230-volt system meant she would be in safe hands in the UK.

On arrival at Southampton, TANGO was greeted by two Berthon representatives who oversaw the lifting and launching of the yacht from the ship before towing it to Berthon’s Marina at the western end of the Solent.

Before lifting the boat and bearing in mind the generator was totally submersed but not used we attempted a start to ascertain its status on arrival; the battery cable connectors were completely corroded and when fiddled with, broke due to a few weeks of corrosion assisted by electrical current running through the water table! The generator was removed whilst the boat under the permanent on-site crane alongside the yard wall and sent to a Westerbeke dealer for a rebuild.

Generator pan showing evidence of salt water corrosion

Our in-house experienced riggers disconnected the rigging and electrics before un-stepping the mast using the same crane carefully stored upon trestles ashore; then TANGO was lifted and moved into Berthon’s heated undercover M Shed, to investigate the extent of damage that had occurred as a result of sea water just breaching the highest of three interior sole board levels.

The engine, only partly submersed, was run up afloat revealing salt water leaking from the oil cooler which was exchanged for a new one sourced from America because of lack of stock in Europe post Covid. The oil sample was ok, but corrosion and other issues loomed large! A new wiring loom, harness and engine mounts were supplied and fitted, and all pulleys were cleaned and painted. The oil pressure switch was corroded, so replaced with the mounts for the plate it attaches to.

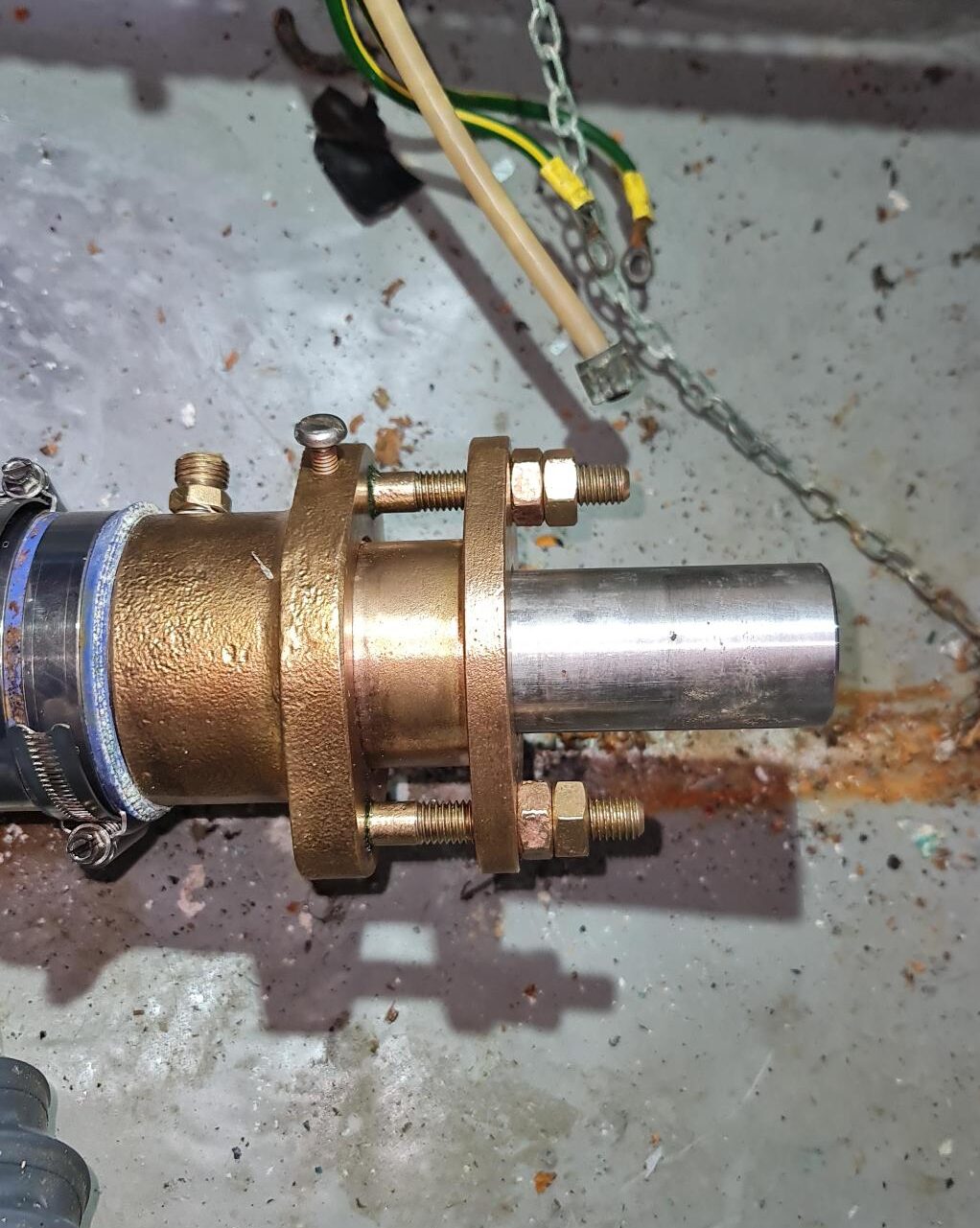

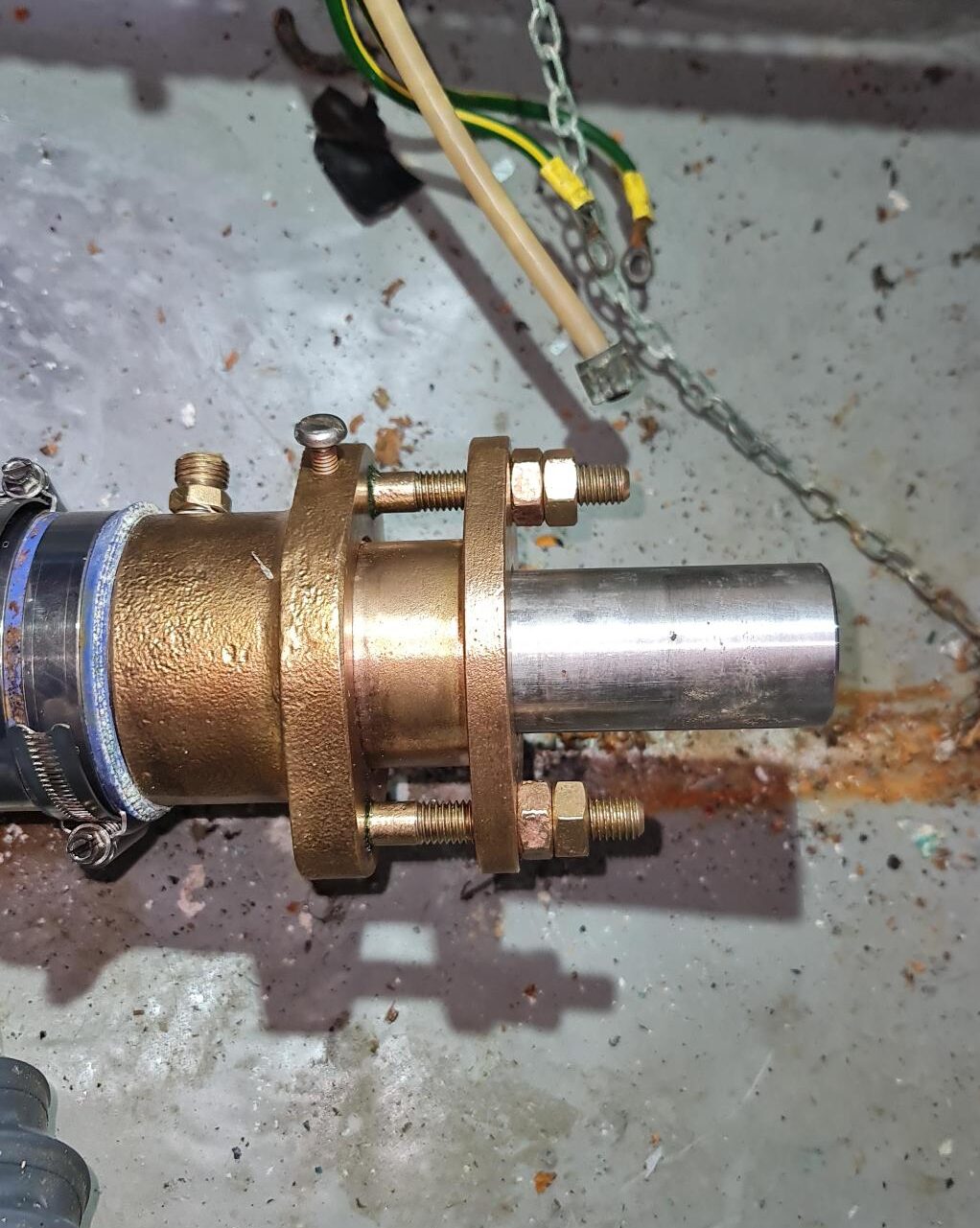

Before and after photos of the stern gland

Before and after photos of the stern gland

Another important part of the refit was an Aquadrive service. This and the constant velocity (CV) axle, also known as a half shaft, that takes power from the boat’s transmission and differential and transfers it to the propeller, were removed and sent to the dealer for servicing and required an overhaul with new race, shaft lock, and new mounting kit. To be safe the CV shaft was replaced, reinstalled and alignment tested.

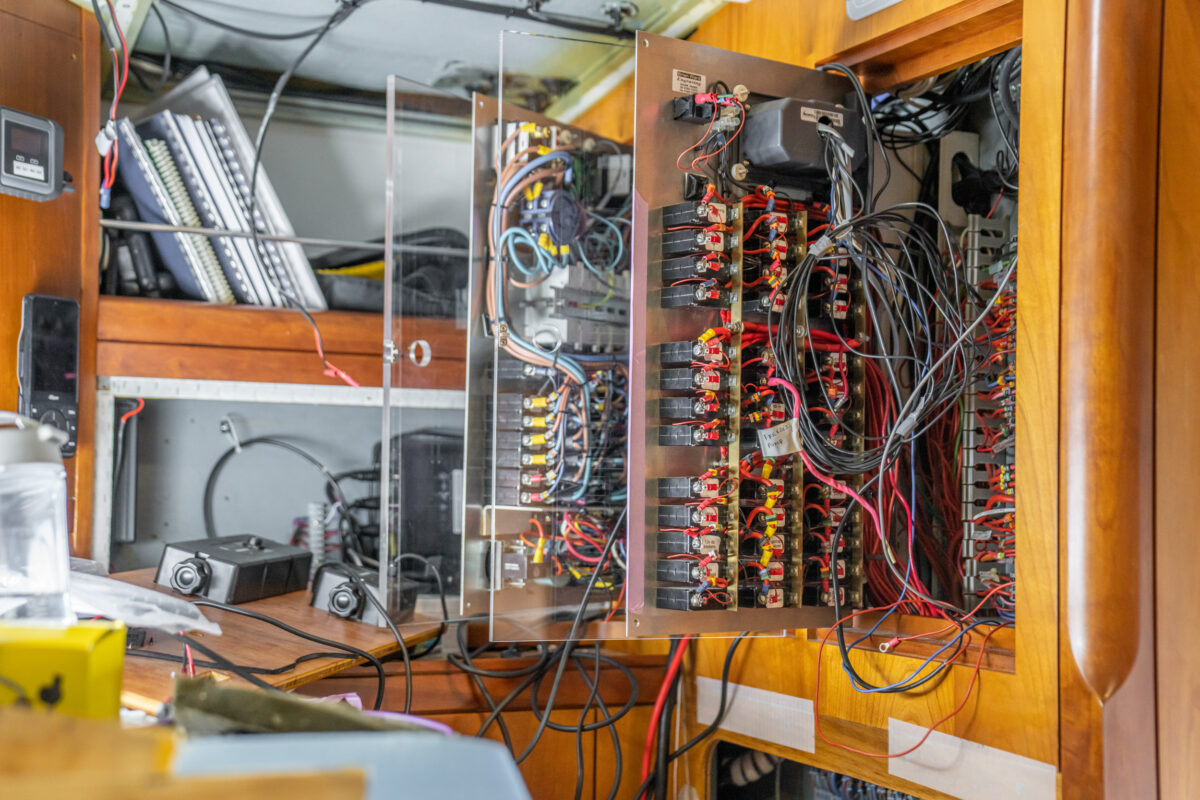

The negative bus bar was completely submerged during the flooding

The negative bus bar was completely submerged during the flooding DC to DC converters showing the height of the flood line

DC to DC converters showing the height of the flood line

The negative bus bar was completely submerged during the flooding

The negative bus bar was completely submerged during the flooding DC to DC converters showing the height of the flood line

DC to DC converters showing the height of the flood line High load cables showing the result of water mixing with electrical current

High load cables showing the result of water mixing with electrical current

By far the largest issue on board was undoubtedly sea water submerged cables. After careful communications with the owner the electricians renewed any cabling that terminated below the high water level; the inverters above the interior waterline were bench tested ashore and made ready to accommodate the increased house battery bank. 24v to 12v DC converters, winch, Autopilot, Windlass, Bow thruster, Laz sockets and entire bonding system cables were replaced in addition to two Mastervolt Gl 7 isolation transformers fitted in the lazarette as an owner’s upgrade.

The main switch board

The DC Panel with a new main negative bus bar, breakers, Wago fittings, Din rail, heavy-duty battery isolator switches, relays and fuses were all also replaced. Whilst the washing machine had suffered the higher-stored microwave, and dishwasher were added to the list for clean set of white goods.

The Webasto heater units in two forward cabins were caput and no longer manufactured, so all four units throughout the boat were replaced to keep continuity. A new fuel pump and filter were built into a plastic box, with new power cables under the sole boards.

As well as keeping the boat warm, the systems to keep it cool required attention, by replacing the air conditioning unit in the forward cabin along with the salt water cooling pump under the galley.

As recommended in the survey report, all through hull fittings were checked by Berthon, and reported. This analysis diagnosed all 39 seacocks needed removing and replacing with new ones and as advised the owner took this opportunity to upgrade to serviceable valves rather than standard ones. This involved disconnecting each hose and removing each valve and cutting out each skin fitting. On carrying out this job, it was discovered that the nuts for the skin fittings had been painted with gel coat, therefore additional work was required to prepare each dry fibre area, creating individual backing pads, epoxy glued to the hull.

The original survey also specified the aft keel bolt was to be extracted to assess the condition. The two nuts were removed from the aft bolt for inspection; due to the length of the bolt and situation, a second surveyor was contacted to assess. The shipwrights set about cleaning up the nuts and thread of aft keel bolts and the second forward bolt nuts removed in the presence of the surveyor, who submitted a positive report to the client. These were then reinstalled, bolts tightened to the torque settings supplied by Oyster yachts.

Engineers carefully removing the rudder.

The rudder was removed to inspect the condition of the stock, bearings and lower skeg fitting, which had water seeping out. Steering cables and quadrant in lazarette and lower skeg retaining fittings were removed with all bolts numbered and labelled as they were originally cut to specific lengths for each hole; therefore, imperative they were returned to the same hole. These were then inspected, as were the bearings and bearing faces in the hull. The lower rudder bearings were replaced before the rudder, and skeg fittings were changed with Arbomast BR on the skeg and Sikaflex on the bolts as specified by Oyster yachts. Once the rudder and skeg were refitted, the last job was to connect the quadrant and steering gear and carry out a final test to ensure everything worked as it should.

Fitting and plumbing the new water pressure pumps.

Fitting and plumbing the new water pressure pumps.

Among the jobs list were many pumps that needed replacing, such as toilet waste, deck wash, forward shower, forward toilet supply, electric bilge, aft shower drain, aft toilet supply, domestic water system, and refrigeration. Each of these pumps required old power cable removal and new cables running in and connecting. Once all works had taken place, the electrical drawings were completed and sent to the owner.

the saloon had a new lease of life

The interior flooded floorboards and table received attention from our experienced Berthon in-house paint team, allowing them to show their varnishing prowess.

The shipwrights provided some TLC to exterior teak deck areas, removing and replacing the caulking where seams between planks was exposed. Once they had completed their work, the Berthon valeters stepped in. Using Wessex 2-part teak treatment, all the external teak was hand scrubbed to remove algae. This was carried out across the grain to ensure the “pitch” was not removed from the timber. Upon completion, a final fresh water wash-down occurred before the Boracol treatment was applied, which helps restore the silvery finish and prevents future algae build-up.

Careful caulking to be flush with the teak

Before the mast was stepped, the riggers had been busy replacing the running backstays using 12mm D2 Marlow Racing (solid white) Dynema cored rope, also updating the passerelle halyard and boom preventers. Then the valeting team stepped in, waxing the mast and boom using “Meguiars” wax.

After TANGO returned to the water, it was time to methodically check all systems that had been changed to ensure everything was working as it should be. This included all pumps that had been commissioned, the Webasto heating system, all electrical functions including navigation systems, autopilot, depth, rudder for leaks, and all the pumps that had been changed during the boat refit. Once all systems were working as they should, and any issues that arose during the rigorous checks were corrected, it was time to load personal items back on board, protection from the interior joinery removed, floorboards and saloon tables replaced.

Now, time for sea trials; the owner, Project Manager, two engineers, and an electrician took the boat to the Solent on a very wet October morning. With the significant work that was carried out on the engine, it was essential to thoroughly run all the tests and ensure it was in full working order, signed off after final checks, and then ready for its delivery trip to Southampton Docks for its journey back to the Caribbean. The owner had only lost one summer season due to Berthon’s ability to attend to all issues with in-house skilled staff and project management.

TANGO being loaded and secured onto the ship for her delivery home.

TANGO being loaded and secured onto the ship for her delivery home.

TANGO was another fantastic refit and repair job in the Berthon Boatyard using its skills and experience, and as a final testament to the work we do, the owner said:

“As the Project Manager on the Tango refit, Jonny did an outstanding job!!!”

now being enjoyed by her owner in the Caribbean.

For the latest news on TANGO, see our recent blog TANGO sets sail – Berthon.